Laboratory for Additive Manufacturing

The research includes the development of new materials in collaboration with the Advanced Materials Center to design high-performance parts through a specific manufacturing process with possibly pre- and post-processing. Some of the basic and high-class equipment in the IMR center are as follows:

Metal Additive Manufacturing

SLM SOLUTIONS - SLM 280

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high-volume metal additive manufacturing part production and prototypes.

- 280 x 280 x 365 mm build envelope

- Multi-laser (twin)

- Multi-material

Small size 3D Printers FDM

Makerbot

- Build Volume: 305 L x 305 W x 457 H mm

- Layer Resolution: 100 microns

- Filament Diameter: 1.75 mm

- Supported Filaments: PLA (Polylactide) & MakerBot Tough PLA Filament

- Build Plate: Injection-molded Polycarbonate ABS

- Onboard Camera: 320 x 240 resolution

- Software Compatibility: MakerBot Print Software

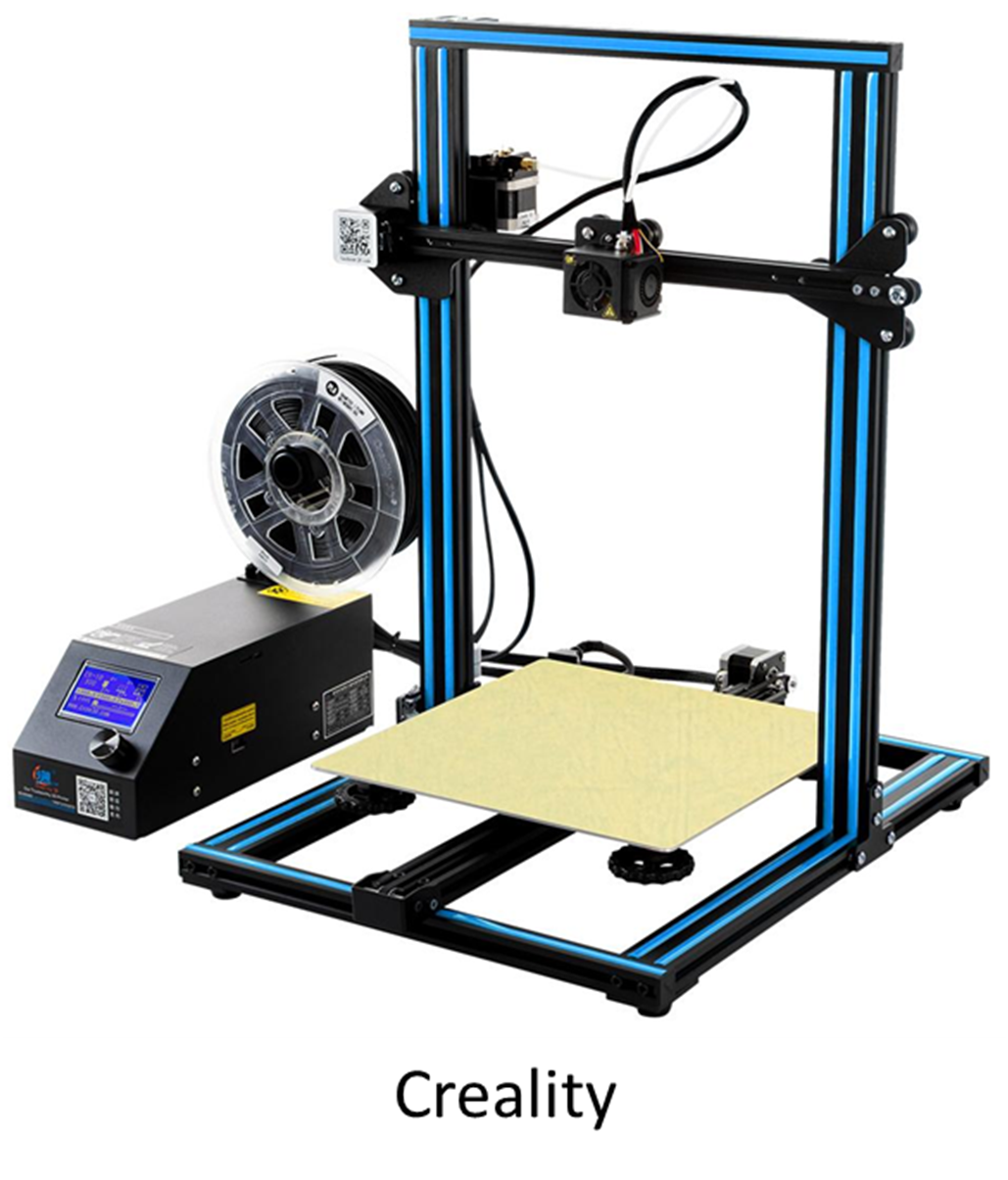

Creality

- Build Volume: 300 L × 300 W × 400 H mm

- Print Speed: Normal: 60 mm/s, Max: 100 mm/s

- Filament Diameter: 1.75 mm

- Supported Filaments: PLA, ABS, TPU, Carbon Fiber

- Software Compatibility: Cura, Simplify3D, Repetier-host

Prusa

- Build Volume: 210 L x 210 W x 250 H mm

- Max. Print Speed: 100 mm/s.

- Filament Diameter: 1.75 mm

- Supported Filaments: PLA, ABS, TPU, Carbon Fiber

- Software Compatibility: Cura, Simplify3D, Repetier-host

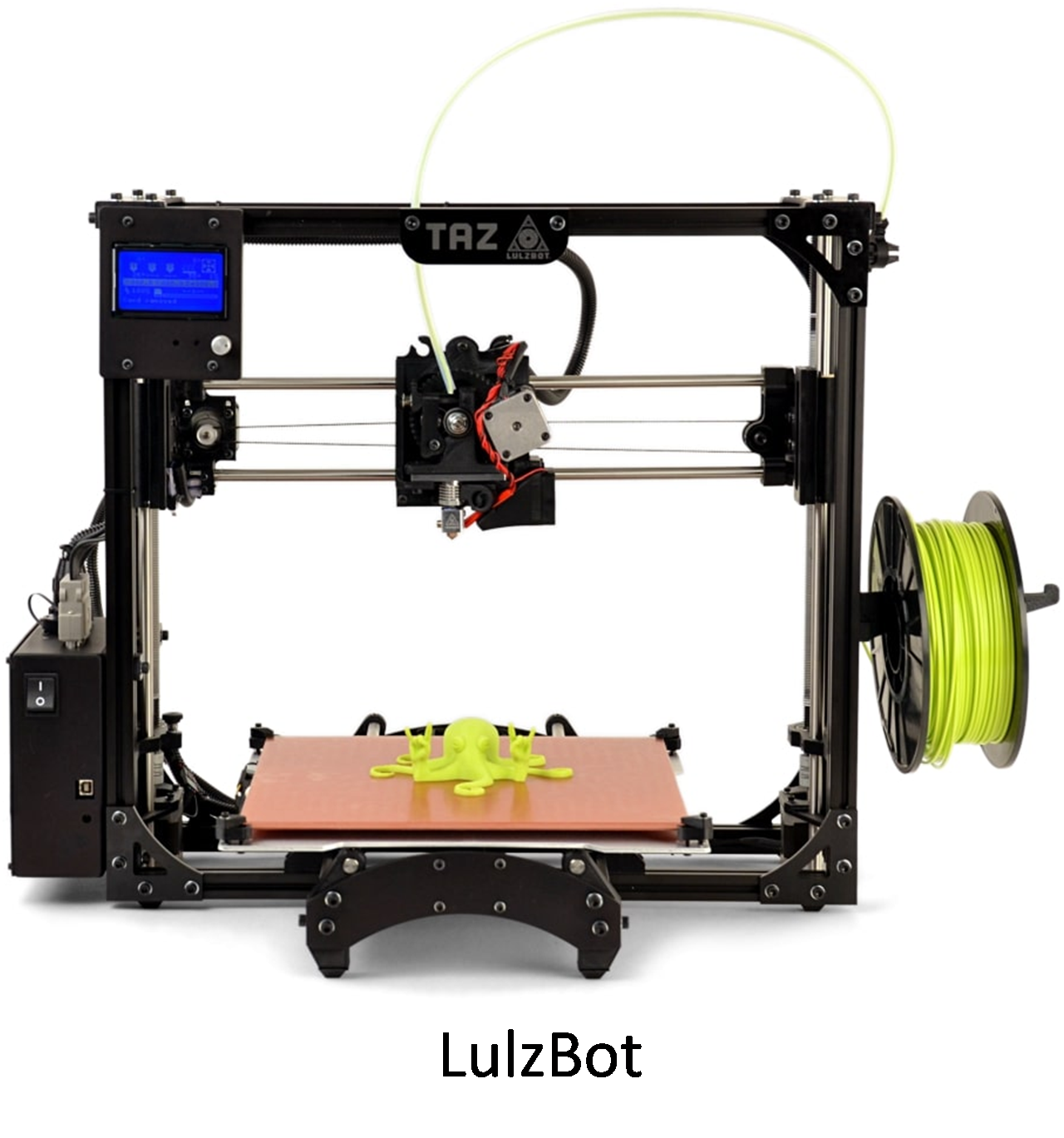

LulzBot

- Build Volume: 298 mm x 275 mm x 250 mm (11.7 in x 10.8 in x 9.8 in)

- Max. Print Speed: 300 mm/s

- Filament Diameter: 3.0 mm

- Supported Filaments: ABS, PLA, HIPS, PVA, Polyester, PETT, Nylon, PETG, conductive PLA and ABS, UV luminescent filaments, and more everyday plastics

- Multi-Software Compatible: Cura LulzBot Edition - Standard, OctoPrint, BotQueue, Slic3r, Printrun, MatterControl, and many more

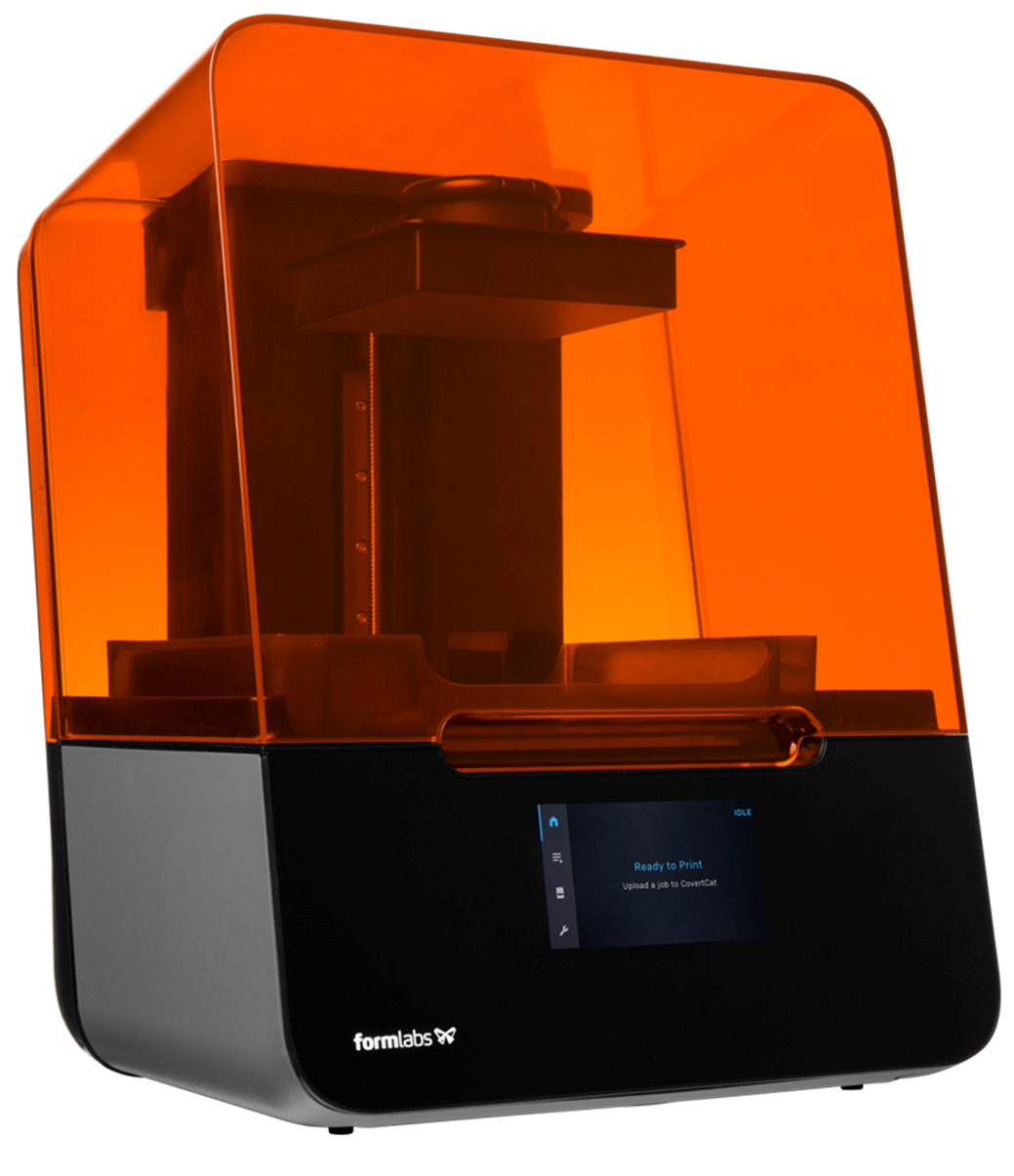

Stereolithography 3D printing

- Build Volume: 145 L x 145 W x 185 H mm

- Laser Spot Size: 85 microns

- Print Speed: 1-3 cm/hour

- Materials Compatibility: Standard, engineering, and biocompatible materials/resins

- Software & Workflow:

- PreForm software for model preparation and slicing

- Form Wash and Form Cure post-processing stations for cleaning and curing