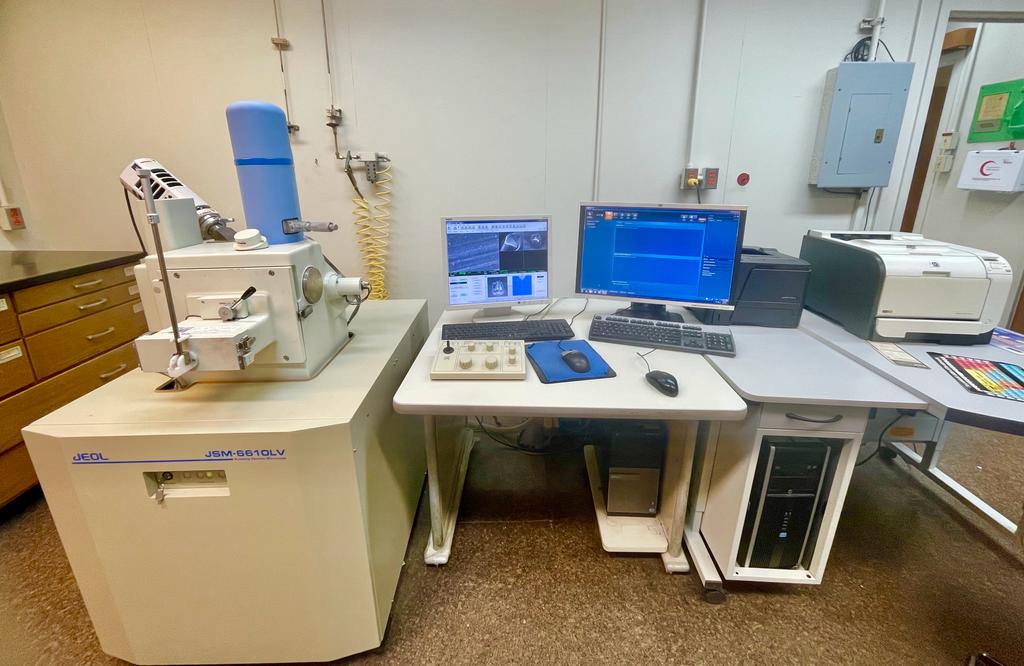

Scanning Electron Microscopy/Energy Dispersive X-Ray Spectroscopy (Sem/Eds)

Scanning electron microscope (SEM) provides a high depth of field at large magnifications permitting a detailed study of the surface topography of materials. Examination of individual grains, dendrites, fracture surfaces, precipitate phases and corrosion products is routinely performed. Energy dispersive x-ray spectroscopy (EDS) coupled with SEM is used to determine chemical composition of micro-features.

Capabilities

- Imaging at high depths of field at large magnifications

- Imaging resolution of 3nm

- Secondary electron imaging, surface topography of materials

- Backscattered imaging of un-etched surfaces

- Low vacuum mode to examine non-conducting samples such as polymers

- Microchemical analysis of microstructural features such precipitates, phases, etc.

Facilities

- Model JEOL 5800LV- Tungsten filament, automated stage with X, Y, Z, tilt and rotational movement, airlock chamber, up to 30KeV accelerating voltage

- Materials identification, non-destructive chemical analysis, imaging of surface topography and microstructural features

- Computerized controls where data is obtained, stored and analyzed efficiently by a PC interfaced to the SEM

- Chemical analysis is performed using efficient EDS standard less method

- Charging effects are reduced by employing low vacuum mode

Location Scientist In-charge

Center for Engineering Research Name: Mr. AbdulKhaleq Bomwzah,

Phone: 860-4956 Phone: 860-1241