A fractional distillation column for hydrocarbon separation

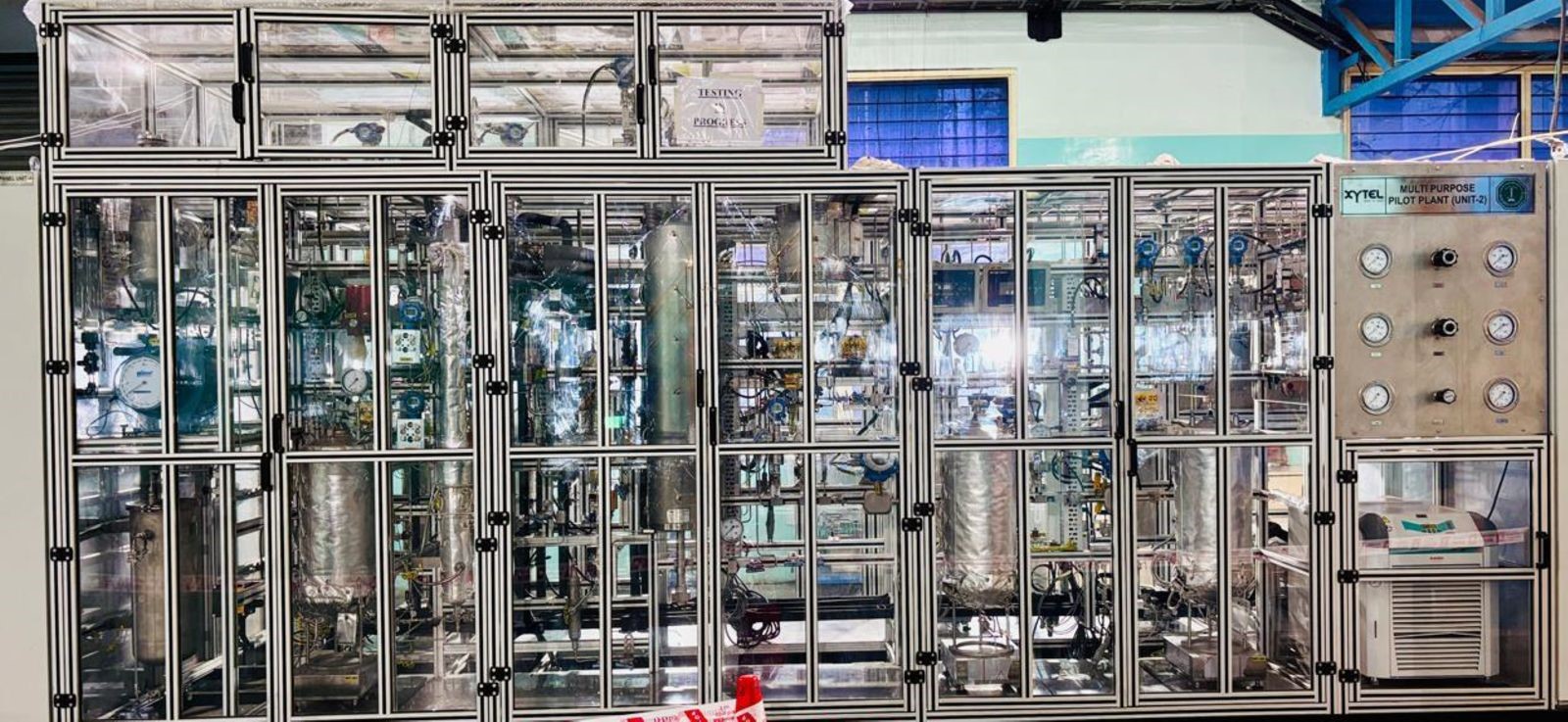

A continuous fixed-bed unit for evaluating catalyst performance using liquid and steam feeds.

A fixed-fluidized bed unit to measure activity of catalysts to convert heavy oil to chemicals

A fixed-bed unit to measure activity of catalysts to convert heavy oil fractions to fuels

Licensed catalytic cracking unit with different reactor configuration without regeneration

Dual reactor system for removing sulfur from crude oil and for upgrading heavy oil fractions

Dual reactor customized to handle wax for low carbon fuel production using CO2 and H2