Construction & Building Materials Lab

The Construction & Building Materials Lab at IRC-CBM is a comprehensive research facility that supports the development, optimization, and performance evaluation of advanced construction materials and systems. The lab integrates multiple specialized sub-laboratories, including:

- Structures and Concrete Lab

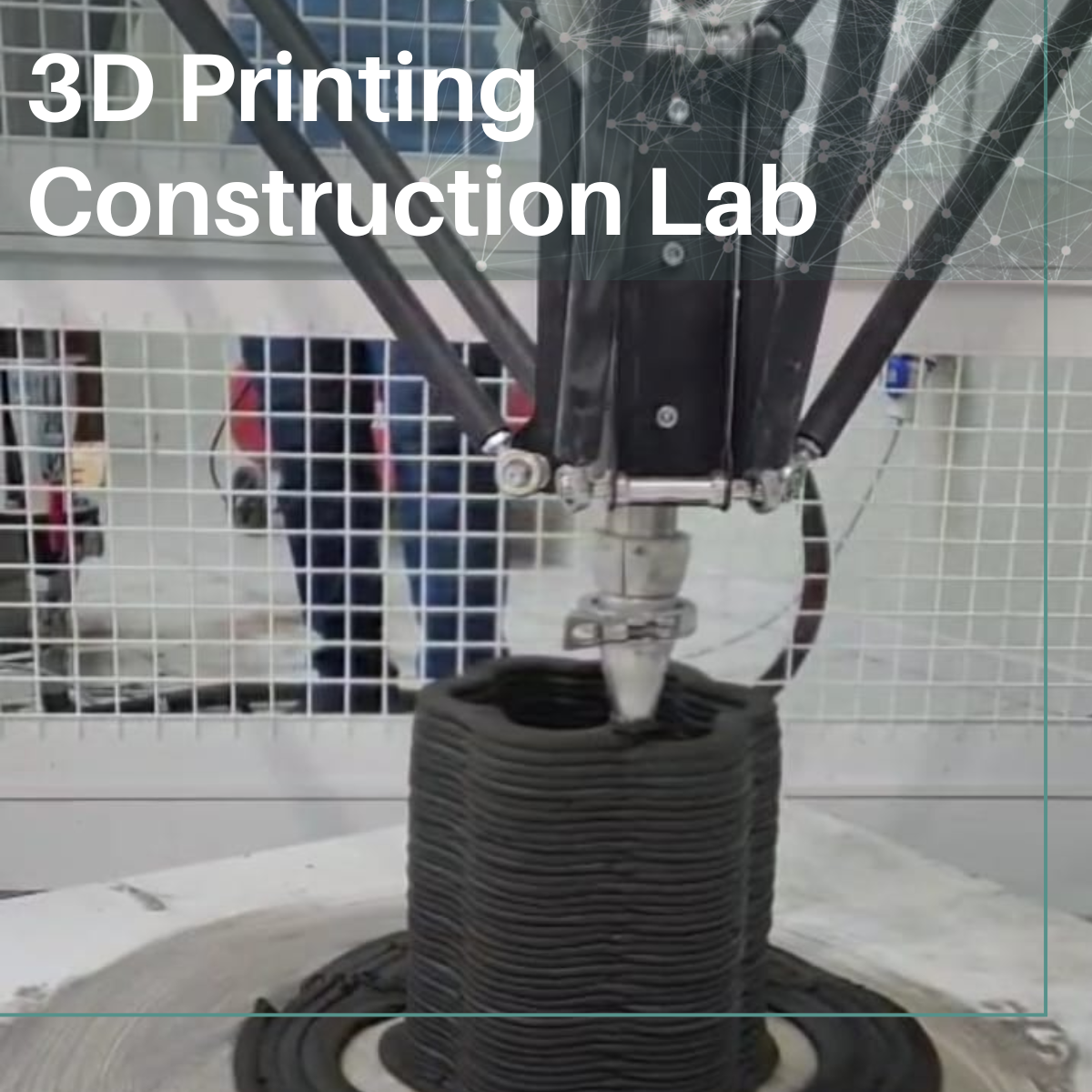

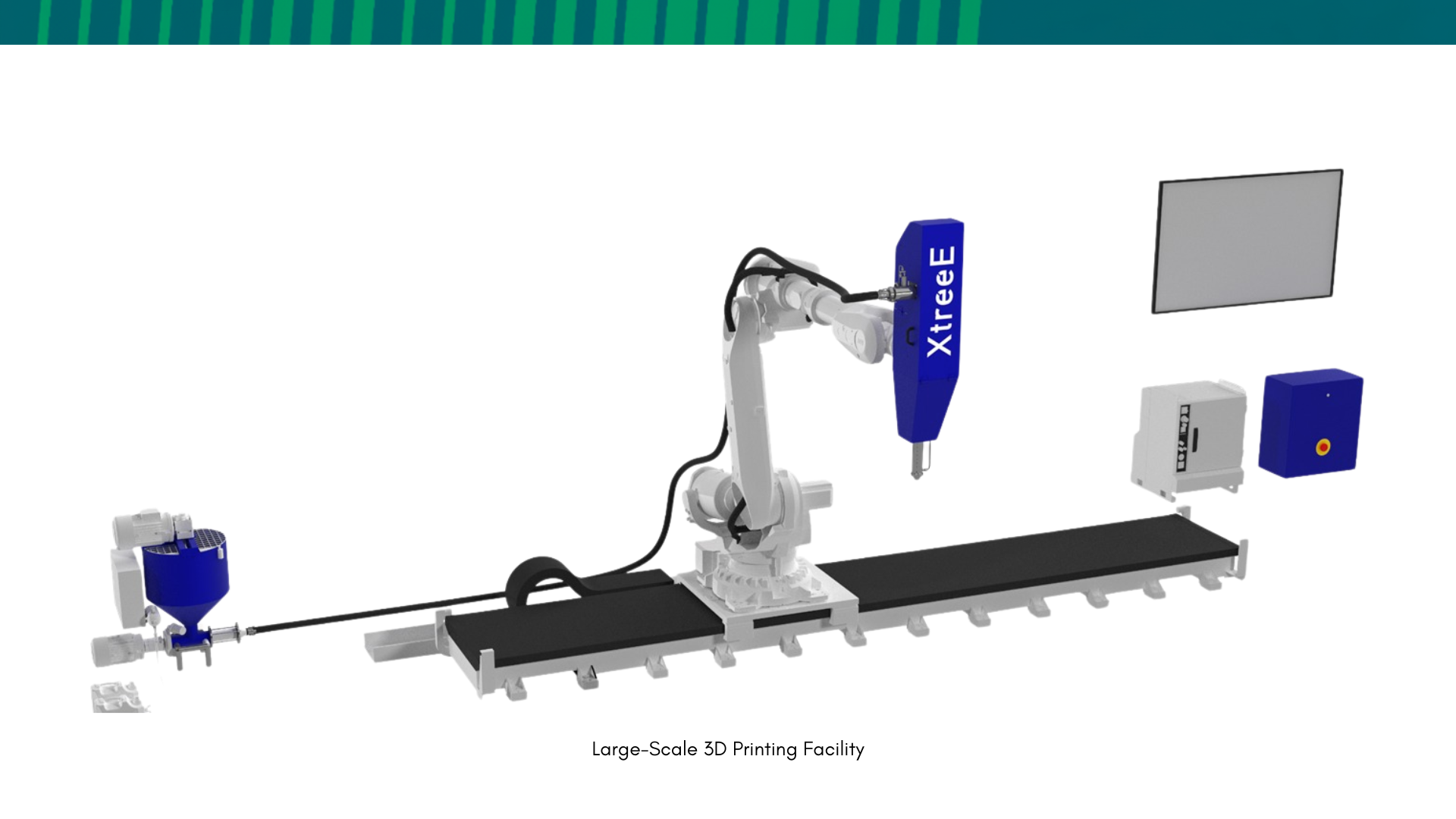

- 3D Printing Construction Lab

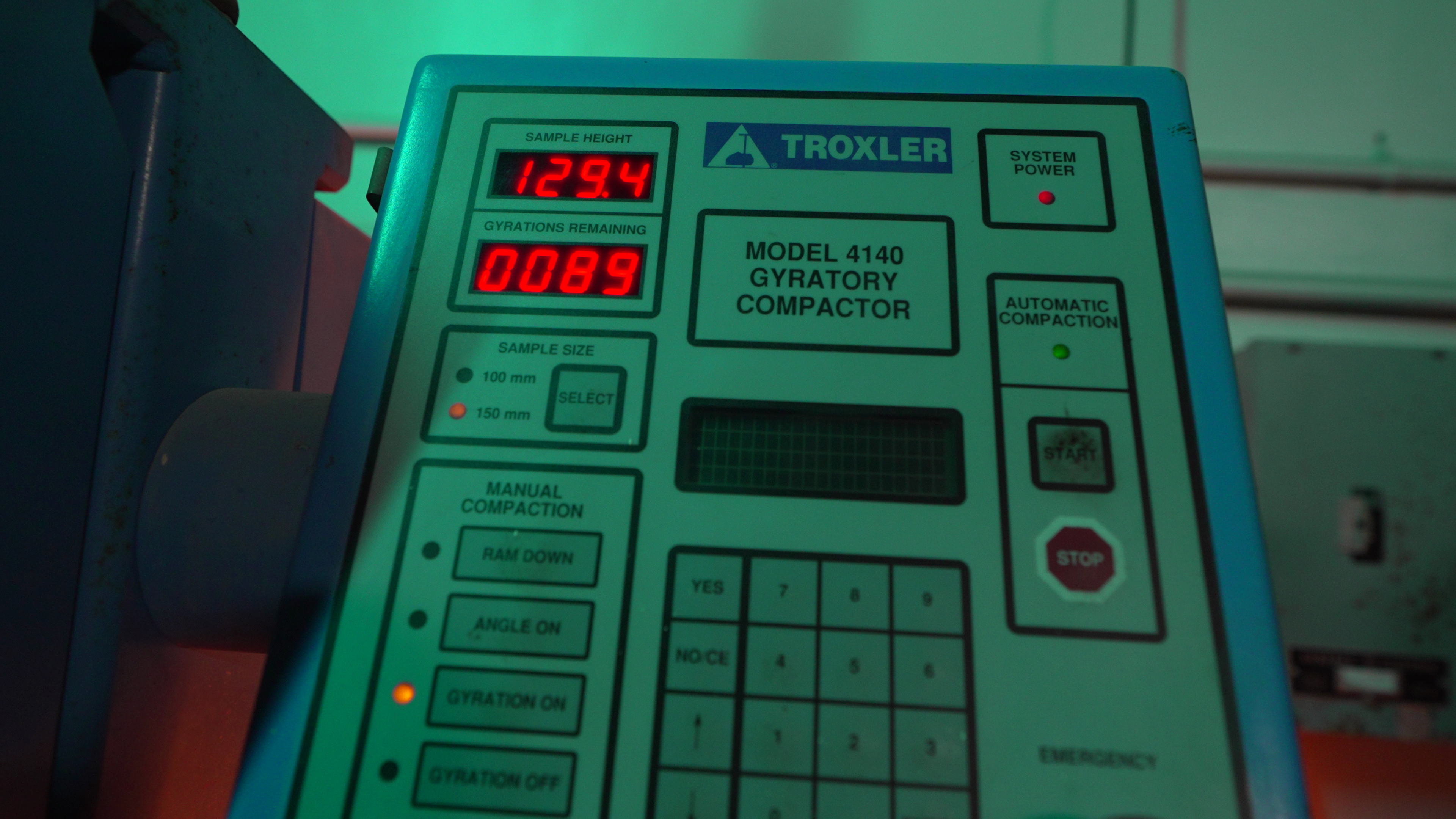

- Asphalt & Pavement Materials Lab

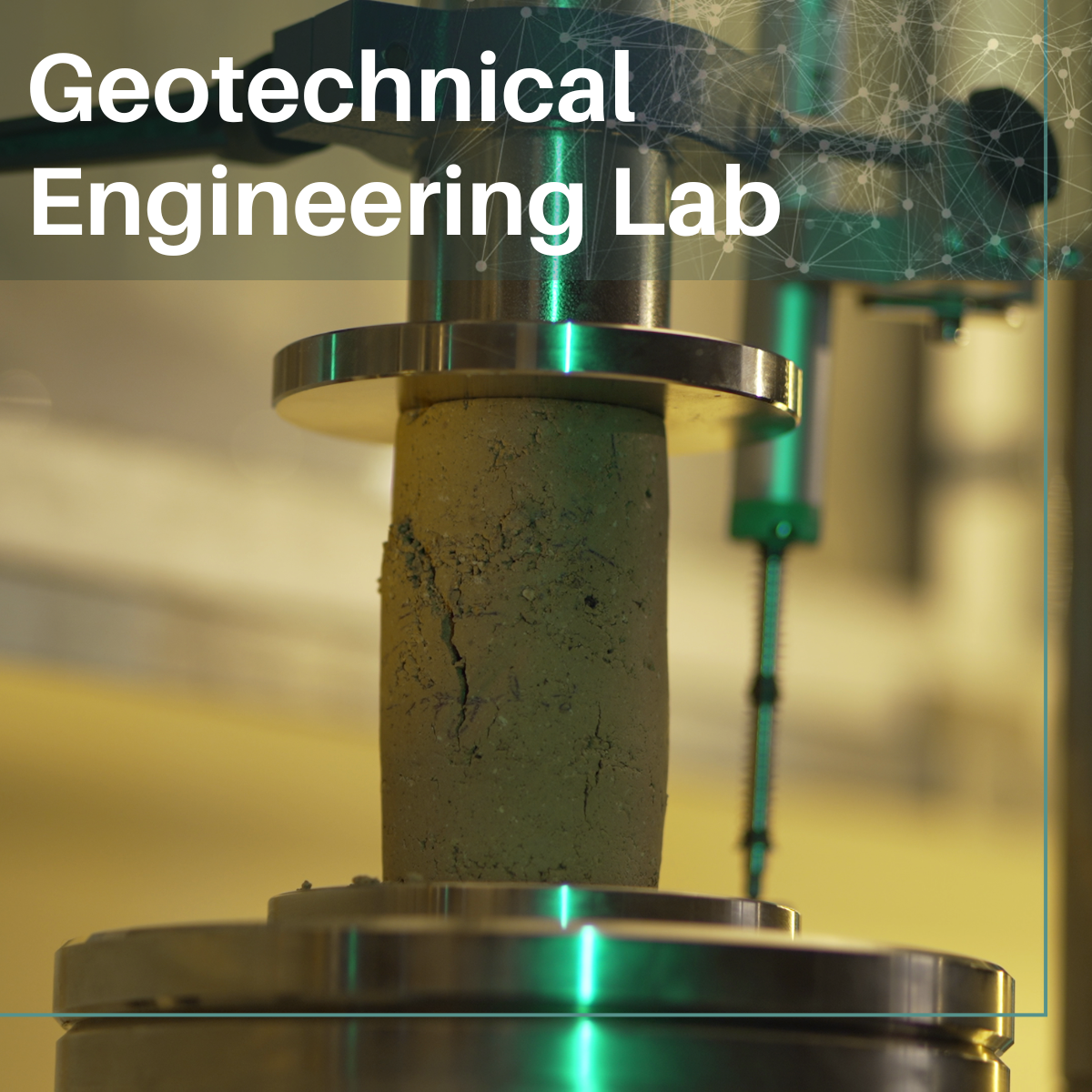

- Geotechnical Engineering Lab

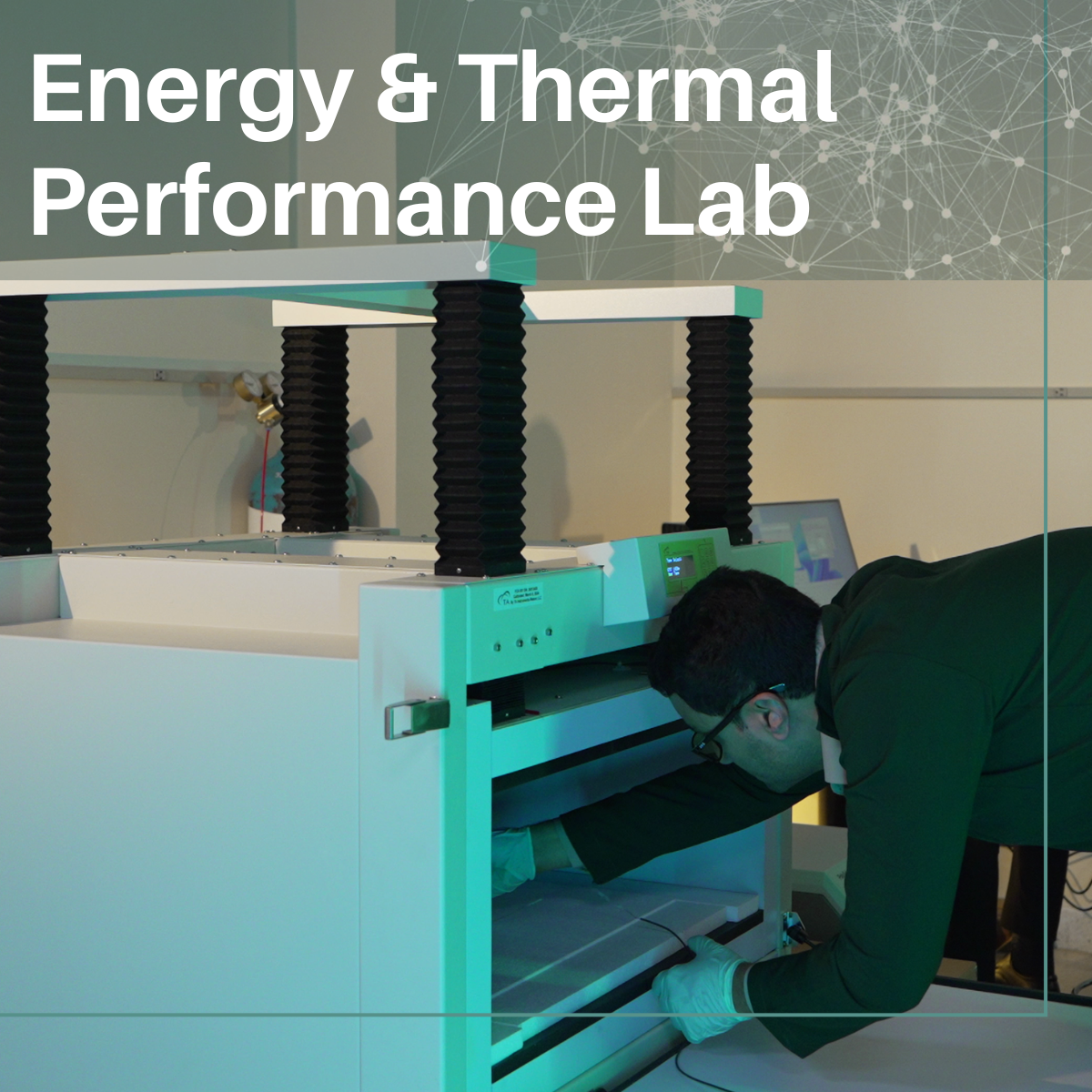

- Energy & Thermal Performance Lab

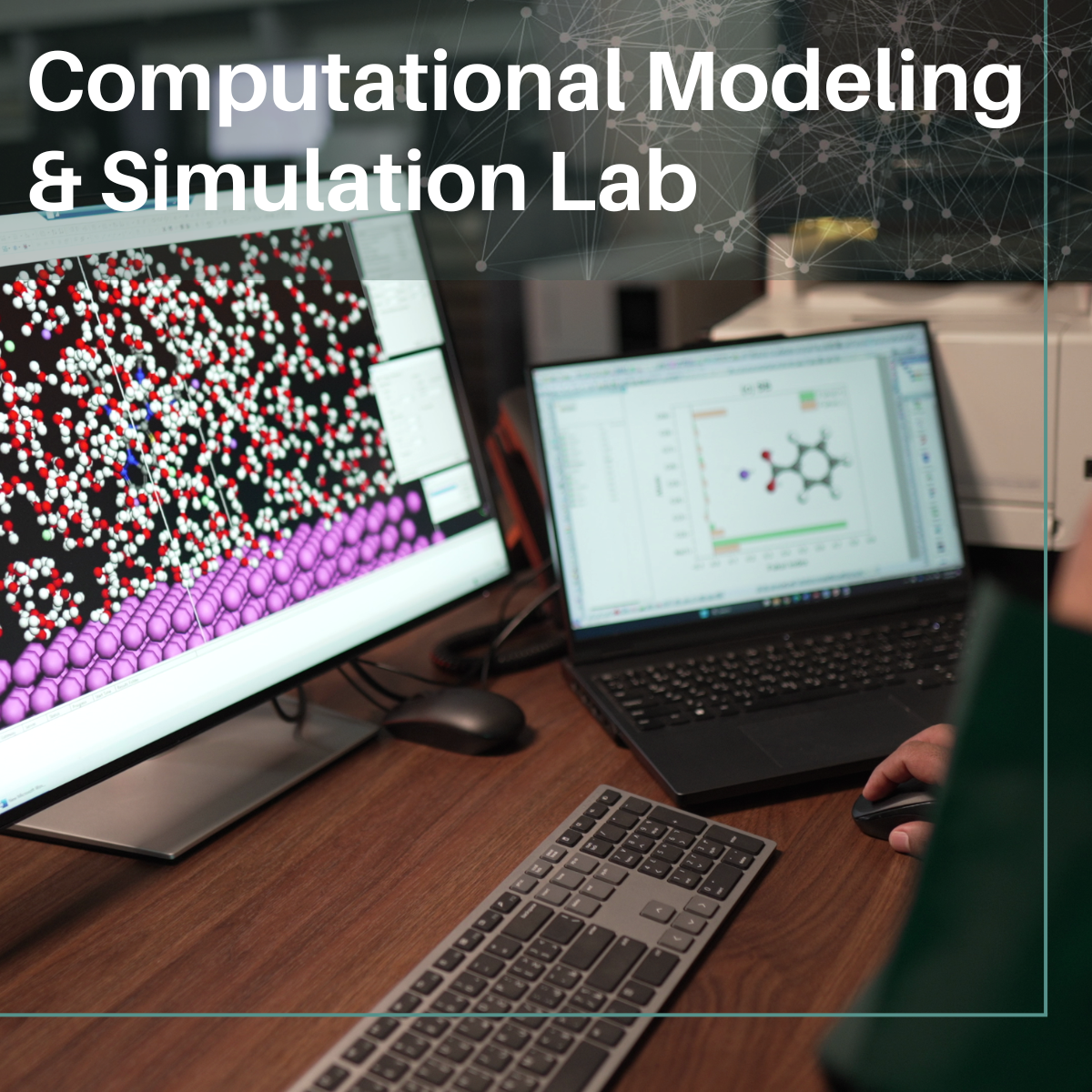

- Computational Modeling & Simulation Lab

Each sub-lab is designed to address a specific aspect of building materials research—from mechanical performance and durability to digital construction, thermal behavior, and sustainability. CBML is equipped with state-of-the-art instrumentation, allowing researchers to conduct full-spectrum investigations from experimental to computational modeling.

Key Facilities and Capabilities

Automatic Compression and Flexural Machine (5000 kN) | 3D Concrete Printer (Delta WASP) | Water Bath |

Compression Machine (2000 kN) | Large-Scale Robotic 3D Printing Facility (XtreeE) | Accelerated Curing Tank |

Hydraulic Cylinder (600 tons) | Planetary Mixer for UHPC

| Brick Machine |

Cyclic Triaxial Automated System (DTS-9) | Large Trolley Furnace | Plastic Crusher Machine/Jaw Crusher |

Automatic Large Direct Shear System | High-Temperature Furnace | Sieve Analysis System |

| Electromechanical Shear Testing Machine | Vacuum Oven, Bench Ovens, Analog Ovens | Vibrating Tables & Vibrating Poker |

| Heat Flow Meter (Fox800) | Controlled Temperature Curing Tank | Concrete Workability Testing Tools

|

| Hot Box Chamber | Hobart Planetary Mixer | Shake Tables |

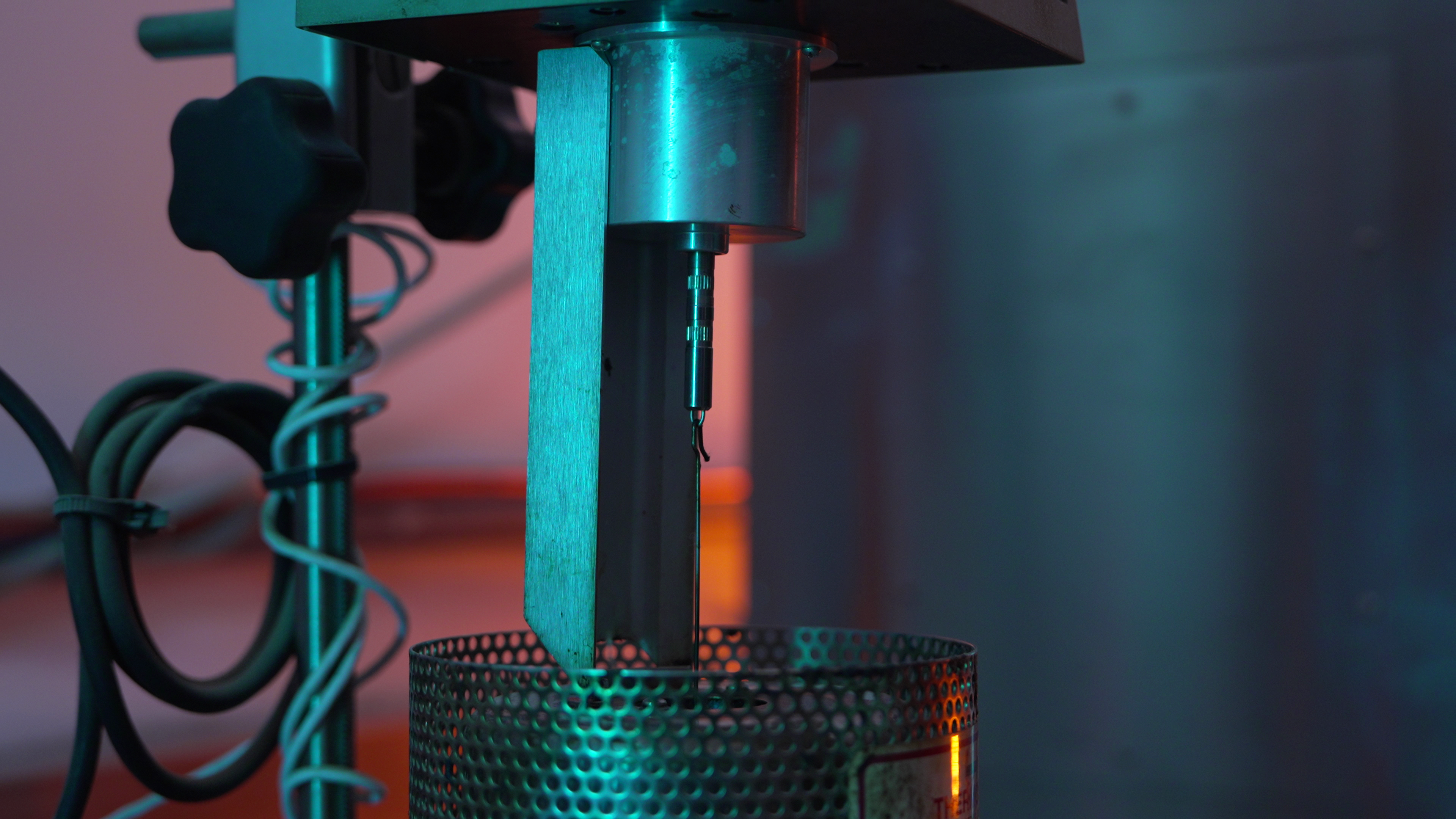

Focuses on mechanical testing of concrete and structural elements, including compressive and tensile strength, shrinkage, and thermal response. The lab is equipped with advanced systems such as 2000 kN and 5000 kN compression machines, and 1000 kN and 250 kN Instron universal testing machines with integrated data loggers. These facilities enable precise load application and real-time data acquisition, supporting research on concrete, steel, and composite systems. This lab plays a critical role in evaluating structural performance and enabling innovations in sustainable and high-strength materials.

|  |  |

|  |  |

|  |  |

|  |  |

Specializes in large-scale additive manufacturing of construction materials. Equipped with two advanced medium- and large-format 3D printers, the lab supports research on automated construction, including the use of printable cementitious and alternative materials. It is a key enabler of digital construction innovation within IRC-CBM.

|  |  |

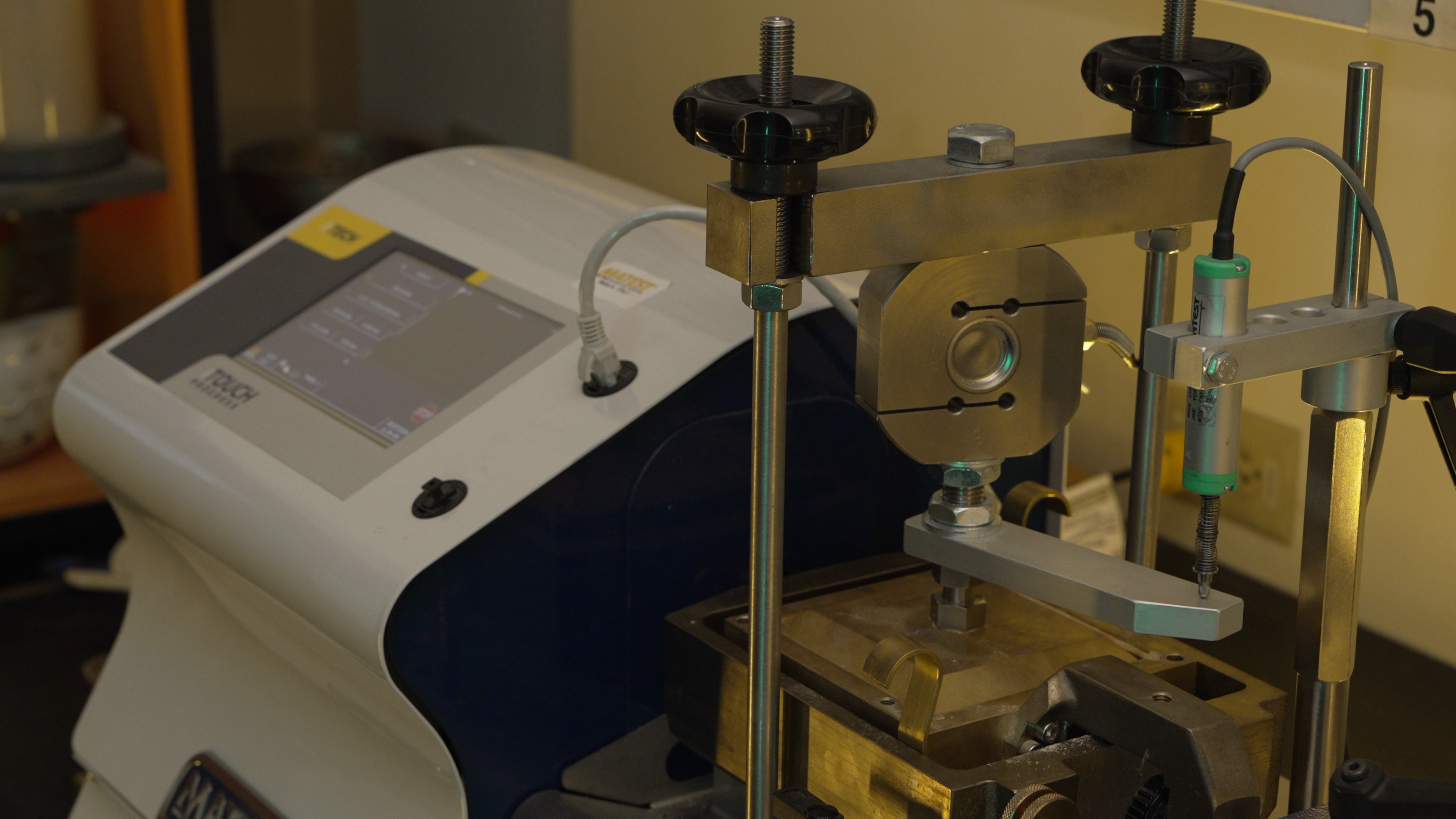

Supports advanced testing and design of asphalt mixes and binders. Facilities include Marshall and Superpave mix design systems, Dynamic Shear Rheometer (DSR), Bending Beam Rheometer (BBR), Brookfield Viscometer, Rolling Thin Film Oven (RTFO), and Pressure Aging Vessel (PAV). For mechanical performance, it features four-point beam fatigue testers, asphalt pavement analyzers, and resilient modulus apparatus. This lab plays a key role in research aligned with sustainable infrastructure.

|  |  |

|  |  |

|  |  |

|  |  |

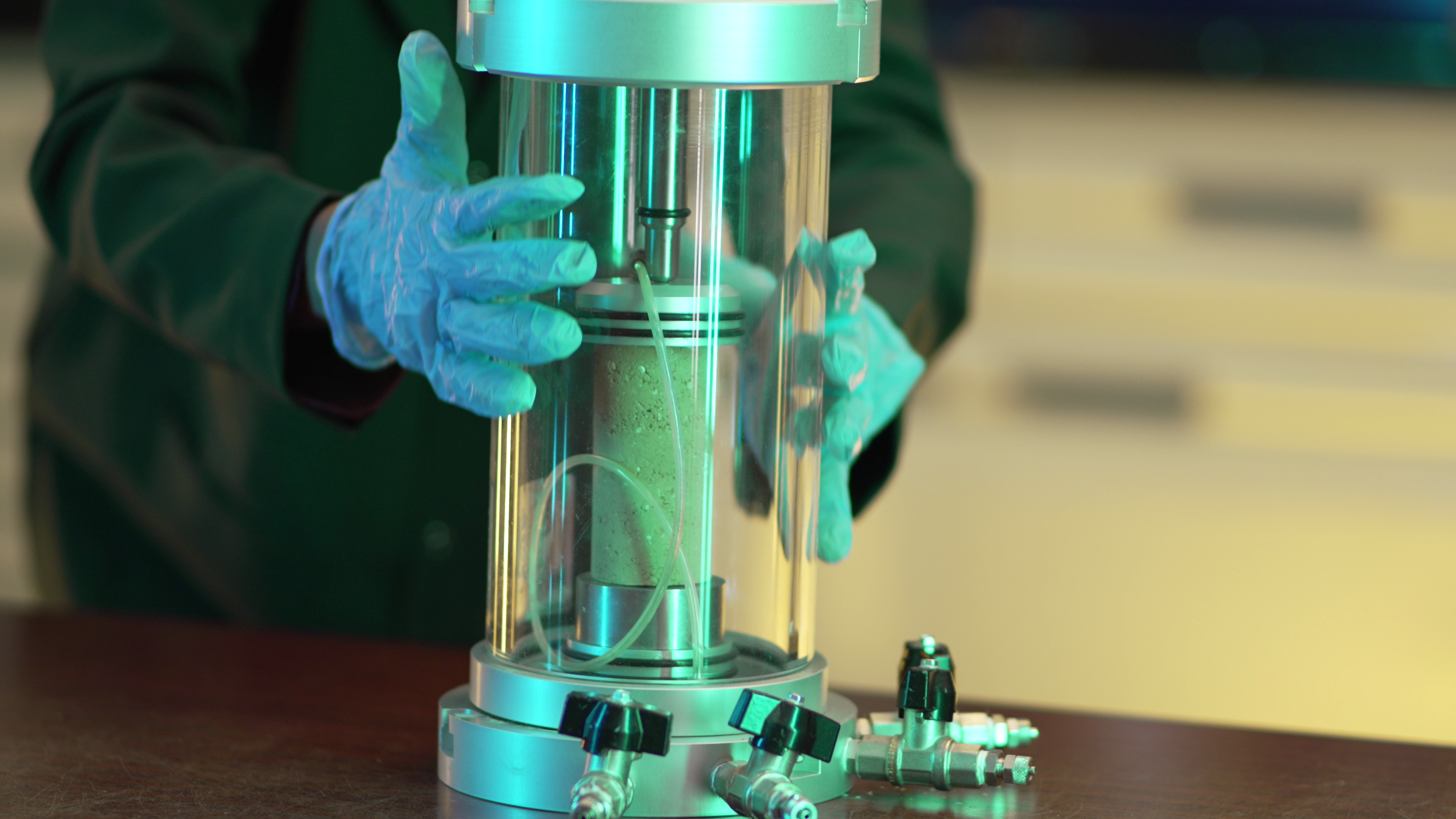

Provides tools for evaluating soil behavior and ground performance under various loading and environmental conditions. Key equipment includes triaxial and direct shear machines, oedometers, unconfined compression strength (UCS) apparatus, and standard tools for soil classification and index properties. This lab supports research in sustainable and resilient geotechnical systems.

|  |  |

|  |  |

|  |  |

|  |  |

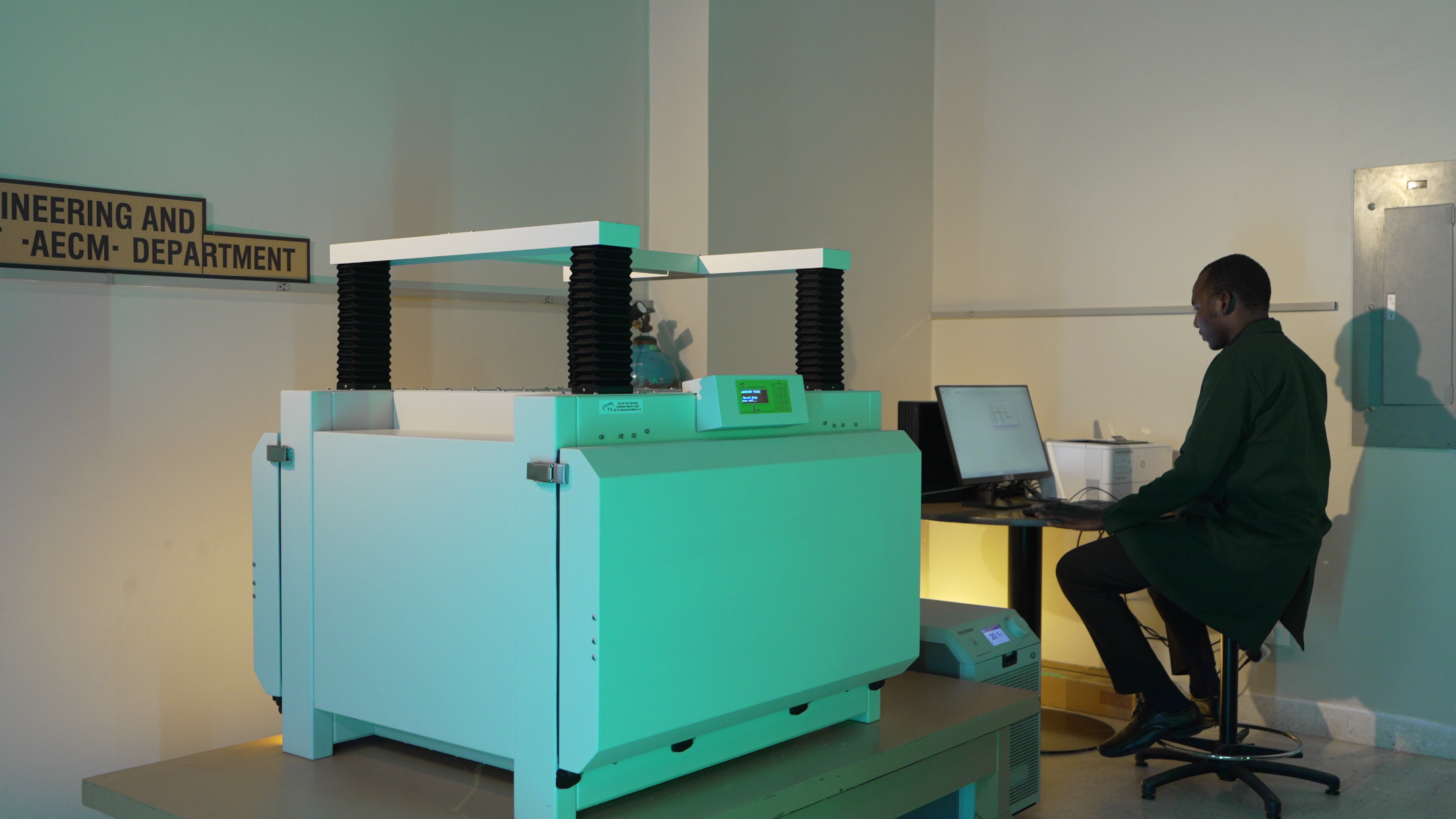

Focuses on evaluating thermal behavior and energy efficiency of construction materials and systems. Equipped with instruments like the FOX 800 for thermal conductivity and resistance measurement, the lab enables precise assessment of insulation and energy-saving materials. A custom-built environmental chamber simulates real-life Saudi Arabian building conditions, allowing full-scale testing of roofs, walls, windows, and building envelopes. This lab supports research on high-performance, energy-efficient building systems.

|  |  |

Enables advanced multiscale simulations for materials and structural systems. Capabilities include Finite Element Modeling (FEM), Discrete Element Modeling (DEM), Density Functional Theory (DFT), and Molecular Dynamics (MD). Supported by three high-performance computing workstations and licensed software such as Abaqus and Materials Studio, the lab bridges experimental work with computational insight, enabling material design from the molecular to the structural scale.

|  |  |