Corrosion Inhibitors

The total cost of corrosion estimated for the kingdom of Saudi Arabia exceeded 80 billion Saudi Riyals in 2011. The total estimated cost of downhole oil and gas production in Saudi Aramco due to corrosion was US$2.29 billion in 2009. Also, Saudi Arabia is also the largest producer of desalinated water in the world. There are 30 desalination plants spread on the east and west coasts of the country. According to Saline Water Conversion Corporation (SWCC), in the year 2007, the expenditure related to spare parts, maintenance, and rehabilitation of its facilities amounted to about 796 million SAR. 50 percent of all these expenditures amounting to about 398 million SAR was incurred due to corrosion and scaling. One of the cost-effective methods of mitigating the corrosion and scale in the oil and gas industry, desalination industry, utilities, transportation, infrastructures, defense, production, manufacturing, etc., is the use of Corrosion and scale Inhibitors Protection (CIP) technology. Currently, almost all the corrosion and scale inhibition mitigation technologies used in Saudi Arabia are imported with a huge cost running into billions of Saudi Riyals yearly to the Kingdom.

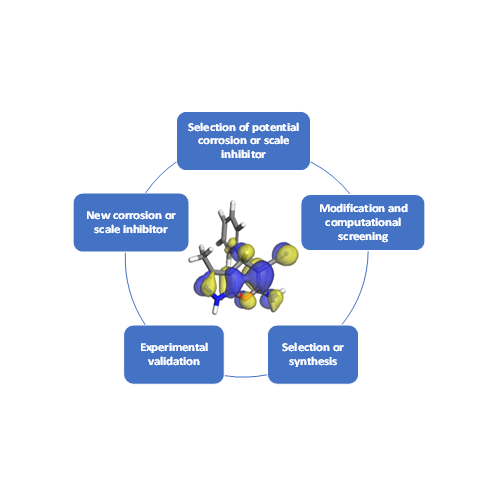

The Corrosion inhibitor research focus area at the Interdisciplinary Research Center of Advanced Materials (IRC-AM) at KFUPM will solve grand challenges related to corrosion and scale in different industrial sectors of the Kingdom’s economy. The state-of-the-art facilities at IRC-AM allow corrosion and scale inhibitor design using computational simulation, Structure-activity relationships of corrosion and scale inhibitors, high temperature and pressure autoclave corrosion and scale inhibitor testing, Synthesis of novel corrosion and scale inhibitors, green corrosion and scale inhibitor development and corrosion testing under extreme corrosive conditions.