Metallic Coatings Development and Testing

Metallic coating plays a vital role in prolonging components' life, providing increased efficiency, improving interfacial sliding conditions, and protecting from environmental attack. They are employed for these applications in many industries, such as manufacturing, automobile, aerospace, biomedical, energy, and petrochemical industries. Metallic coatings are usually deposited to protect surfaces from different material degradation mechanisms such as oxidation, corrosion, erosion, scaling and fouling, environmental deterioration, embrittlement, among others. Developing metallic coatings with superior properties to ensure the sustainability and reliability of processes and components is central to the objectives of IRC-AM.

IRC-AM is equipped with several state-of-the-art equipments for the development, evaluation, and post-deposition treatment of the metallic and ceramic-based coatings for various applications. These include:

- Physical vapor deposition

- Low-pressure cold spray

- Ball milling machine

- Furnaces

- Tribometer

- Instrumented Indentation System

- 3D Optical profilometer

The cathodic arc physical vapor deposition system has the capability of depositing all forms of nitride-based and carbide-based coatings, single, graded, and multilayer designs. Coating properties (such as hardness, structure, chemical and temperature resistance, adhesion) can be precisely controlled. In this process, an arc with a diameter ranging from microns to just a few tenths of a micron is run over the solid, metallic coating material, causing it to evaporate. The high currents and power densities used to cause almost complete ionization of the evaporated material and, thereby, the formation of high-energy plasma.

Cathodic Arc PVD system at the IRC-Advanced Materials

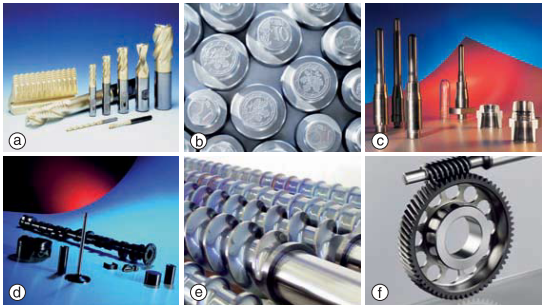

Typical applications of PVD coatings: (a) Cutting tools (b) Embossing dies (c) Moulding tools (plastics) (d) Engine components (e) Extrusion screws (f) Starter motor pinion

Specifications of the PVD System include:

- APA Arc technology

- Patented Power Etching AEGD for excellent coating adhesion

- Bipolar pulse substrate voltage (BIAS)

The Center is also equipped with a low-pressure cold spray capacity for deposition on a wide range of substrates. The Cold Spray process uses the energy stored in high-pressure compressed gas to propel fine powder particles at very high velocities (500 - 1500 m/s). The powder particles are accelerated and moderately heated to a certain velocity and temperature where on impact with a substrate they deform and bond to form a coating. As with the other processes, a fine balance between particle size, density, temperature, and velocity are important criteria to achieve the desired coating. The Low-Pressure Cold Spray can be used to apply a metallic layer to various plastics. A wide range of metals can be deposited, e.g.:

- Aluminum

- Zinc

- Copper

- Tin

- Nickel

- Babbitt

- Gold

- Silver

- Platinum

- Mixtures of the above materials

The Low-Pressure Cold Spray system at the IRC-Advanced Materials

The main properties of the coatings:

- High adhesion (30-80 MPa)

- High cohesion (30-80 MPa)

- Homogeneity of the surface

- Low porosity (1-3%)

- High electrical conductivity between the coating and the substrate

- Any coating thickness (20 microns to 10 cm)

- Roughness of the surface coating is Rz = 20-40

- Processing coatings produced by conventional machining methods

- Coating may be applied to any metal, glass, and ceramics

The Center has developed competency in testing and evaluating the mechanical, adhesion, scratch resistance, oxidation, corrosion, friction, and wear/erosion properties of the developed coatings according to relevant industry standards. With the advanced furnace facilities at the Center, the center’s researchers can use post-deposition heat treatment programs to tune the microstructure/phases of the coatings to attain improved and specific properties suited for unique and challenging applications.