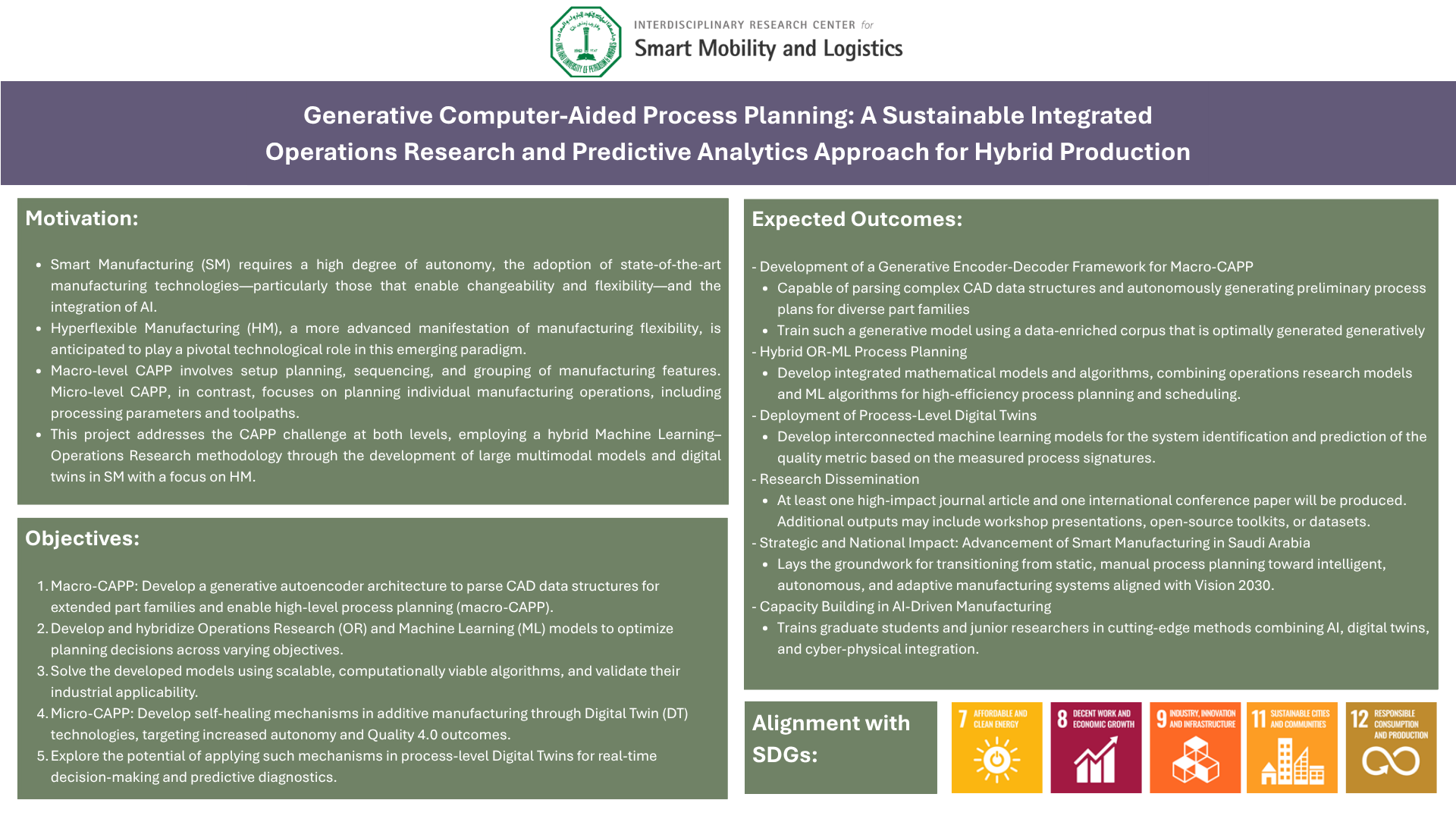

Generative Computer-Aided Process Planning: A Sustainable Integrated Operations Research and Predictive Analytics Approach for Hybrid Production

PI: Dr. Ahmed Azab

CoI: Dr. Moayad AlNammi

CoI: Dr. Moayad AlNammi